Circular Economy blog # 3 - vanPlestik

In my last couple of weeks here at Amsterdam Smart City I will present you a series of interviews on the circular economy with companies here in the Amsterdam Metropolitan Area.

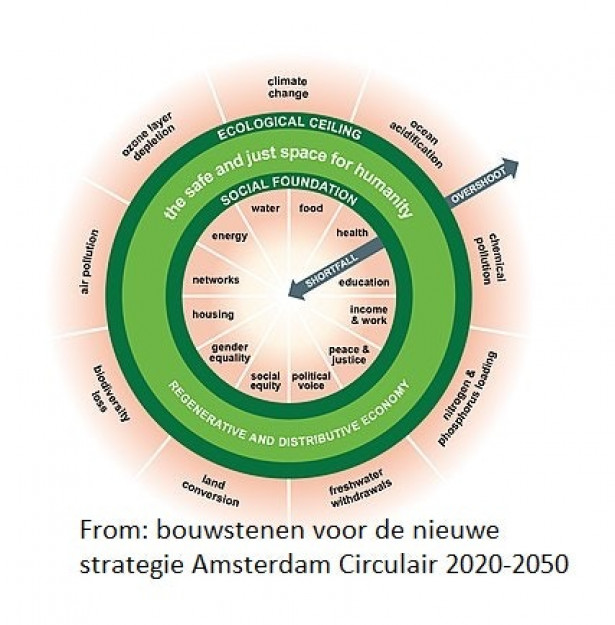

In this third post I will introduce you to vanPlestik a company that contributes to one of the building blocks of the City of Amsterdam: to stimulate high-value recycling of complex consumer goods.

In a fully circular economy, products that can no longer be repaired or reused should be recycled in order to retrieve valuable resources. However, this is for most consumer goods a difficult process. For plastics and textiles for example this often lead to a loss of value.

I would like to introduce you to vanPlestik, a Dutch start-up founded by Nout and Sam. vanPlestik produces new products from recycled plastics by using their own developed and built 3D-printer. For this interview I spoke with Nout.

For which problem is vanPlestik a solution and how did you came to this solution?

Despite that a lot of plastics are already collected separately, we found out that a huge amount is still not recycled. It is a good thing that most plastics are already collected separately in the Netherlands, however a large part still end up in the incinerator. We were surprised and wanted to do something about this problem.

Therefore we asked ourselves: why is not every plastic product produced of recycled materials? We both have a technical background and automatically we started thinking in technical solutions and we found out that the problem is in the shortcomings of the machines that make plastic products. The existing machines were not able to process different kinds of plastics. So, as a experiment, we decided to develop and built a machine that is able to process different plastics. It took us quite some time to develop a prototype and soon we realized we had to make money with it, since it became our fulltime job. We believe that is needed if you want to continue the project and really want to make impact. So that is what we did for the last two and a half year, developing it into a real business.

Where do you get your plastics from and how does it work?

We have several sources where we get our plastics from, plastics form different organizations and companies. For example, sometimes we get plastic coins from organizers of festivals, but also plastics from white goods. Besides this, there are also different kinds of plastics we like to work with and we get these from different sources, to be sure we always have some plastics for our production. However most of our projects consist of different collaborations with organizations with who we are trying to create a project that has a closing loop. This means that we make products for a company that also delivers the secondhand plastics. For example we did a project with HEMA. Their old display furniture had to be replaced and now we are using the plastic parts to produce new garbage cans for their headquarters.

Important is that in order to print new products the plastics we use are already separated. Our machine can only process one sort of plastic at the time. There are two reasons for not processing different plastics on the same time. One it is a difficult and very technical process since different kinds of plastics have different melting points, and second; it is not very circular. When two plastics are combined you create a new sort plastic of less quality and it almost impossible to melt and reuse it again.

How do you contribute to a circular Amsterdam, how circular is your process?

In 1,5 year time we have processed around 2000kg plastic, but this could have been more. In theory the machine is able to process three kg per hour. We have developed and built three more printers so we are able to produce four times as much as we did.

All the products our 3D-printer creates can be processed again and can be used to create new products. However this is not an infinite process since it is mechanical recycling what we are doing and this has a technical end. We re-melt the plastics again and again and after seven times the quality is lacking, we cannot longer guarantee the same quality as after the first time. What we can do is create an inferior product for other purposes. Another solution to this problem is adding newer plastics, plastics that are only recycled once or twice.

Why and how would you scale up the process?

Our end game is not only making new products from recycled plastics, but also making impact. In the end we want to share (the technique of) these machines with the rest of the world, trough open source or other ways. Next year we have our first pilot with an entrepreneur abroad. So upscaling, by increasing our production and increasing our revenue is needed to finance further development of our machines. The three machines we just built are already much more improved than the first version of our 3D-printer. In the end this will result in more work for us, but also in propagating our story and making impact.

In order to create more impact we choose to work with clients we believe have more impact on society, luckily for us we have this luxury. So if it is possible we will always chose for the client with a project that, in our opinion, has more impact.

Your question for the community?

We do a lot of pilots, so our projects are really customized and designed for one specific client. Therefore we have start-up costs for every single project. My question for the community is:

“How could we develop a more general model to create scalable projects, without these start-up costs?”